Design consultant

Today’s challenge for design consultant?

- How to compare different cooling technologies & equipment’s performance to make the right decision?

- How to avoid over-provisioning, resulting in high upfront CAPEX & recurring OPEX costs?

- How to visualize the designed performance of DC up front with varying IT loads?

- Can we predict the ACE parameters, i.e.. Availability, Capacity & Efficiency over the period of the life span of DC with varying IT load before actually built?

- How to predict the impact of cooling failure on the data center resilience?

- Can we predict the transient analysis for 10 or 5 min? see what all equipment’s comes under red line and may lead to downtime?

There are many questions and need to answer before actually built the facility.

The power of CFD simulation tool to create a 3D Virtual Facility (the facility before actual built) allows you to simulate the airflow throughout your design & answer all the questions you have raised.

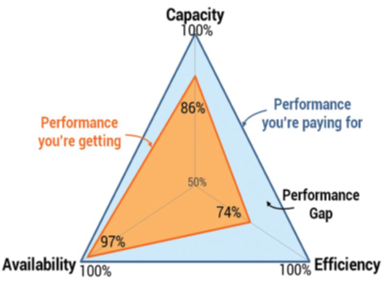

The powerfull 6 sigma CFD software help us to visualize & analyse the performance matrix by using the triangle.

The three ACE variables can be mapped to a simple triangle in order to visually display the performance of a data center at any point in its lifecycle – from initial design and eventual commissioning, all the way through to operations.

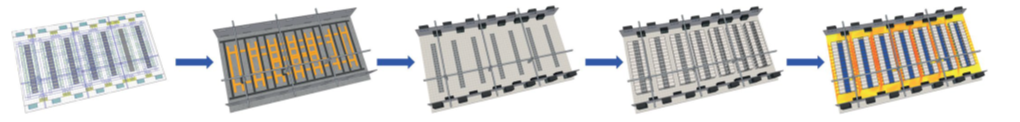

Make Right Choice of Design

6 Sigma CFD software help us compare different cooling technologies & equipment’s performance to make the right decision as per site conditions.

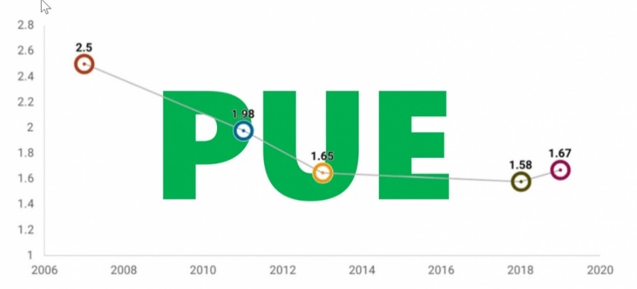

Predicting energy consumption and PUE matrix :

6 Sigma CFD helps to predict the energy consumption and power usage effectiveness before DC built.

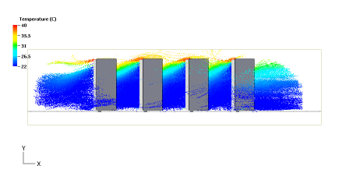

Predicting Transient & steady state analysis to check your data center resilience :

- Predict & visualize the transient analysis.

- Predict & visualize steady state analysis to run failure scenarios with change of IT load.

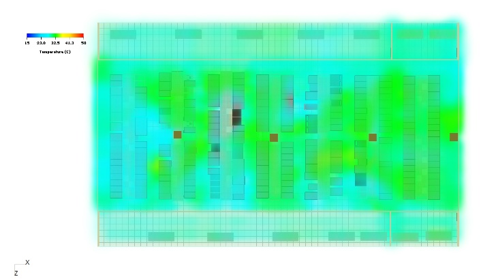

Predict thermal mapping & hotspots :

6 Sigma CFD helps to predict the hot spots in the design before DC built. Hot spots leads to downtime of the Data center

Improve energy efficiency and reduces the recurring OPEX cost :

6 Sigma CFD helps to predict the loop holes in the cooling design like over cooling racks, underfloor pressure distribution pattern, placement of units & return air path, hot & cold air mixing, rack level short cycling of air, based on data it will help us to take corrective action before built DC. Effective utilization of cooling brings tremendous amount of energy savings.

Capacity Planning and Optimization:

6 Sigma CFD helps to predict capacity utilization at rack level & Data center level before DC built

- Rack level : Predict the available Vs used capacity for Power, cooling, U space, network point & rack weight capacity

- Data center level : Predict the available Vs used capacity for CRAC & UPS