Case Study -2 : Enterprise DC

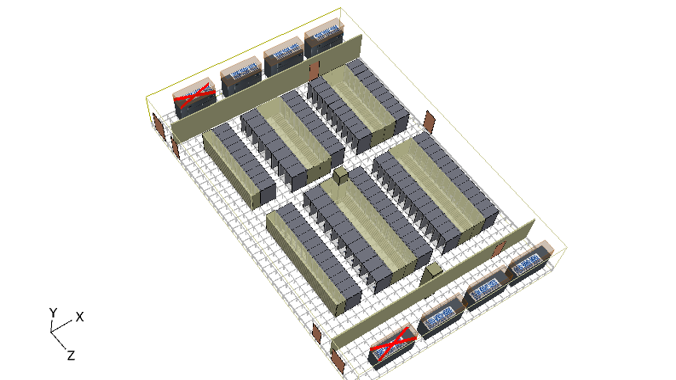

Facility DC Summery: Proposed Design Parameters for new Data center

- Approx. DC area is 4400Sq. ft. (Including PAC room)

- Current IT load planned – 170kW

- Space cooling load : 65kW, (Total cooling load: 235kW)

- UPS : 1x450kVA and 1x350kVA

- Future expected expansion – 100kW additional (Total IT load : 270kW)

- Number of racks – 110 (20no’s – 3phase & 90no’s – 1phase racks)

- Ceiling return distribution system used for recirculation air

- Bottom through CRAC in use

- Designed with 8 No’s of 22TR CRAC units : DX Type

- 6 CRAC units operational with 2 standby

Customer Objectives

- Weight analysis – Rack and raised floor level

- IT Availability – Rack level and at IT equipment level

- Capacity Utilizations : Power, cooling, U space and Weight across lifecycle of data center

- Cooling efficiency : Simulating and predicting the at IT device to rack to data center level

- Resilience : Predict the cooling failure analysis

Other concerns on proposed design

- Do we need 8 units of 22TR CRAC units (8no’sx77kW) to control 170kW present IT load plus planned future IT load? Additional CAPEX and recurring OPEX

- Can we simulate the scenarios to ensure the optimum design ?

- Demonstration of designed performance of DC up front with increase in IT load?

- Is selected design free from hot spot’s when IT load increases?

Enterprise –IT/ITES data center manager decided to use Data center design ratification services (DCDR) to verify and validate the design

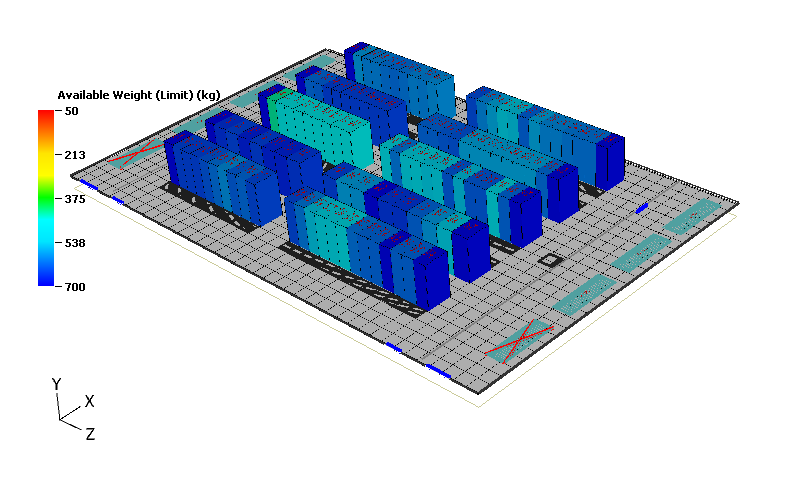

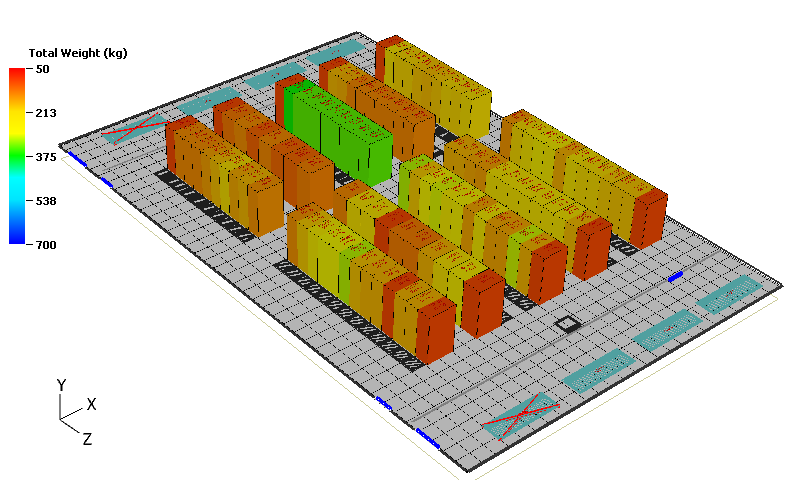

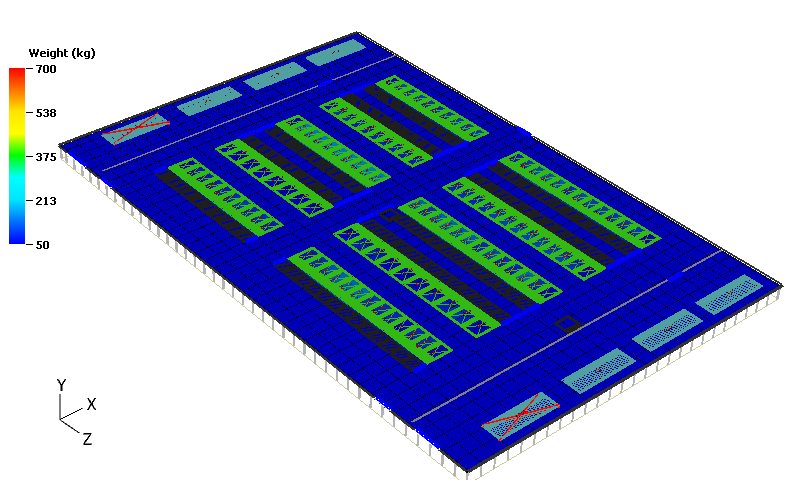

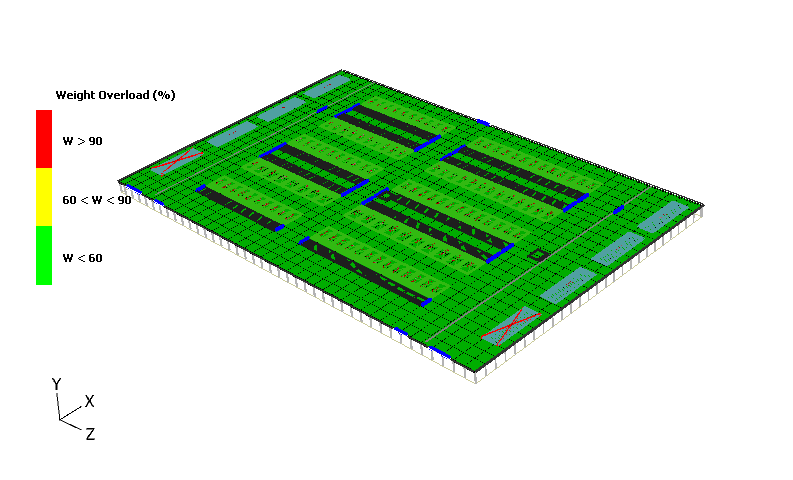

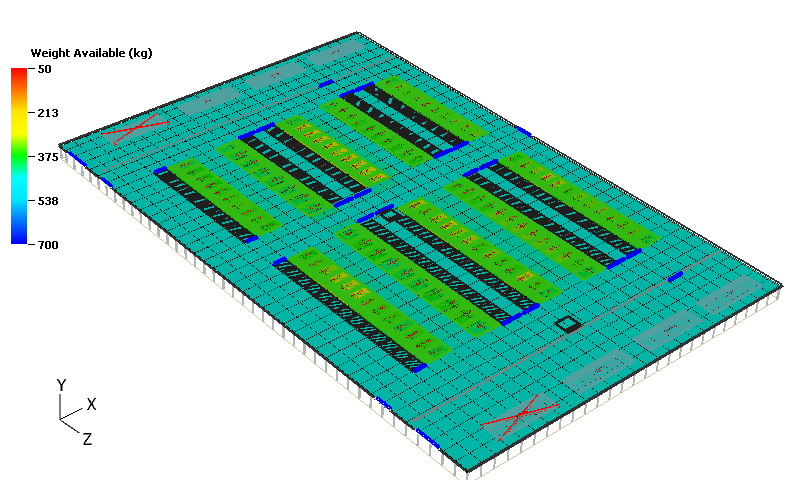

Weight Analysis

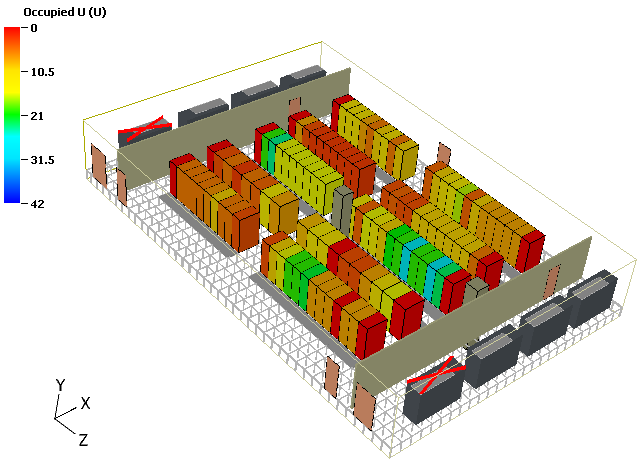

Weight analysis on Rack level (kg)

Weight analysis on raised floor (kg)

IT Availability

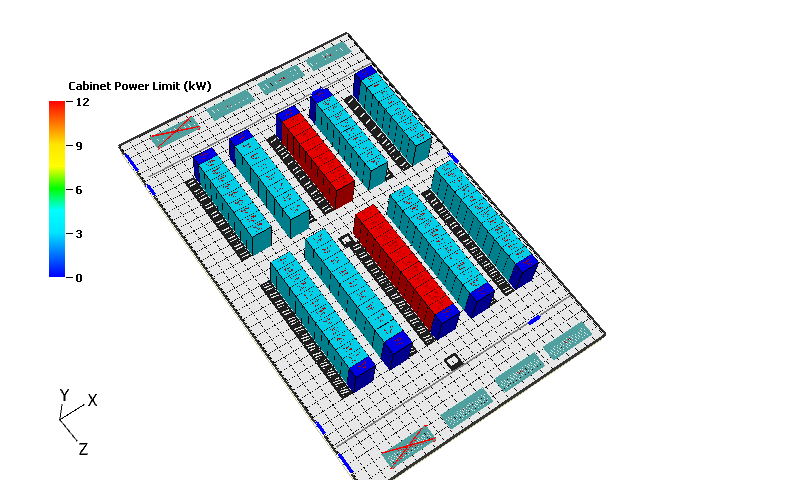

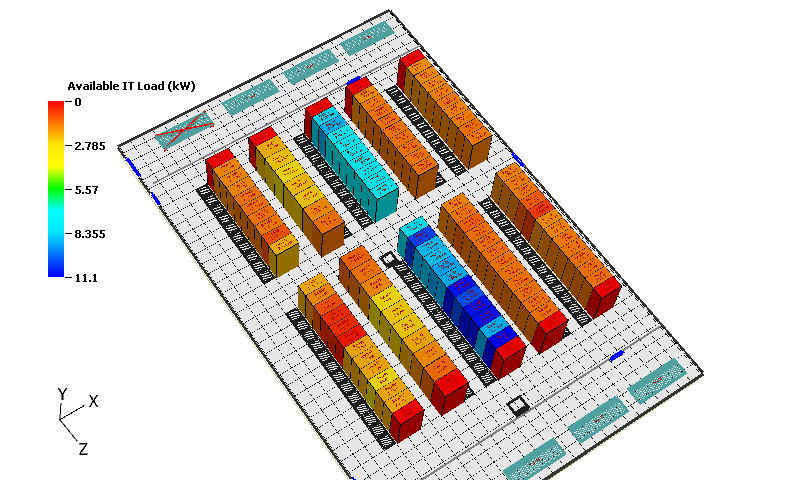

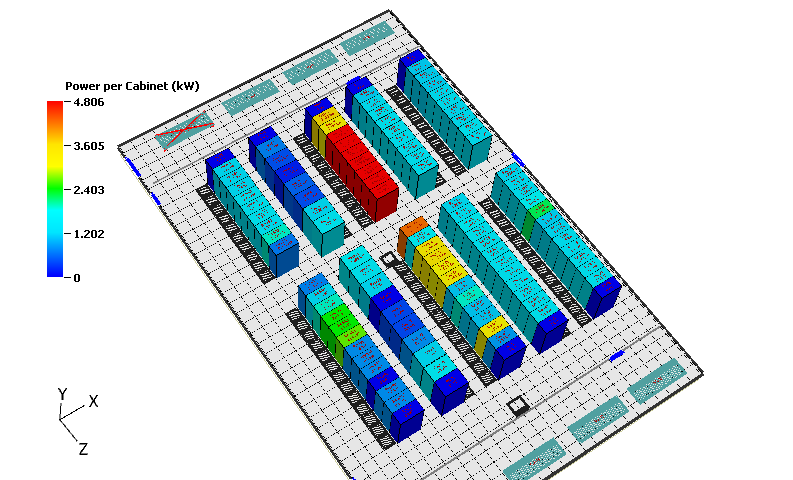

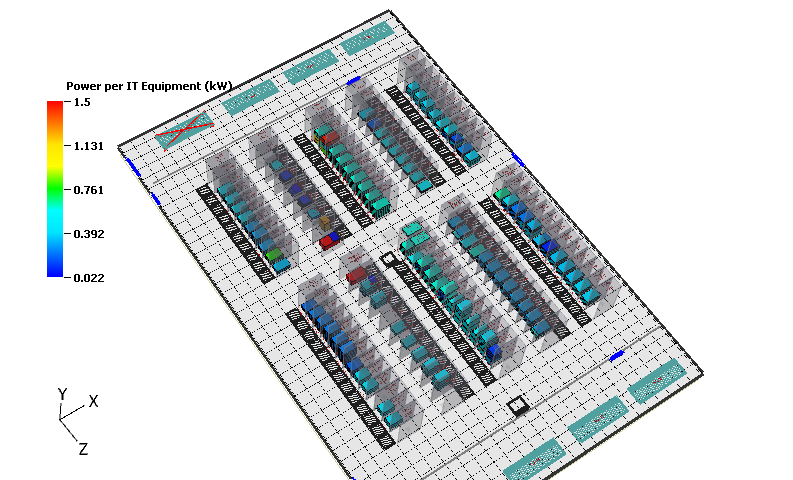

Power (rack IT load) analysis

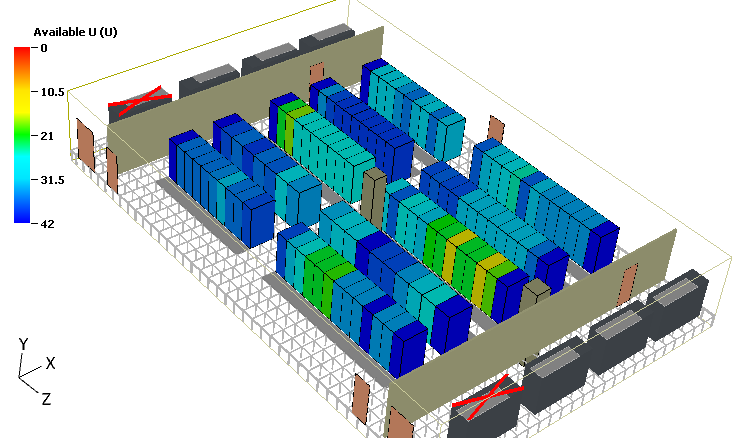

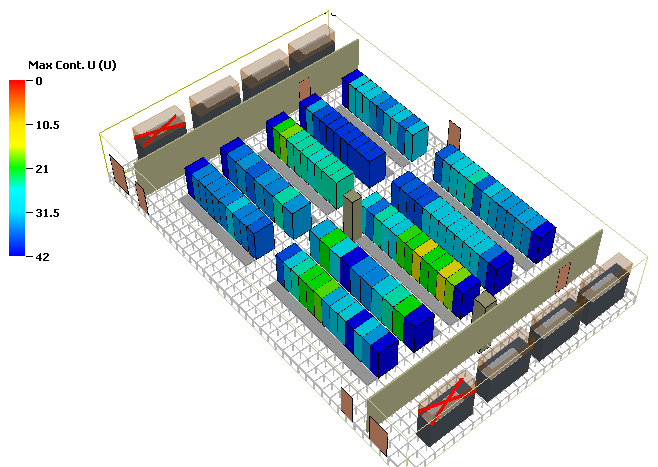

U Space analysis

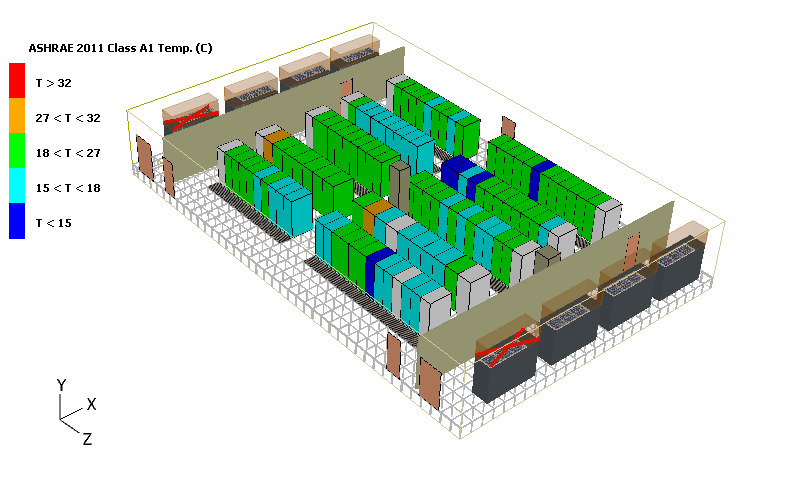

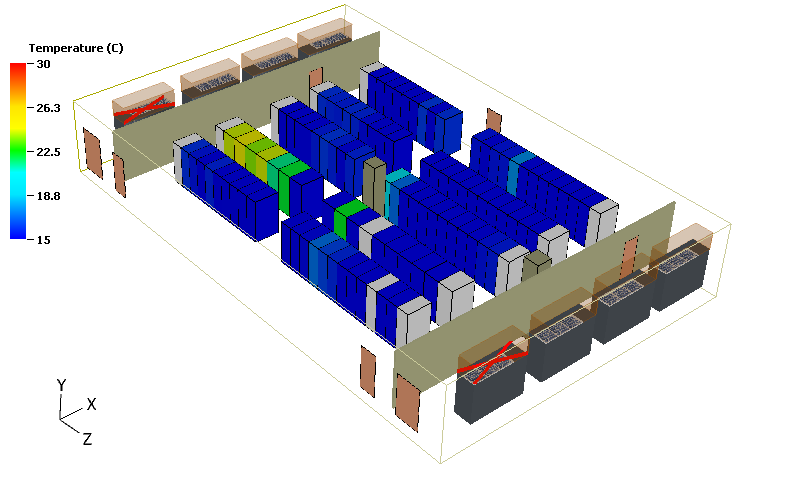

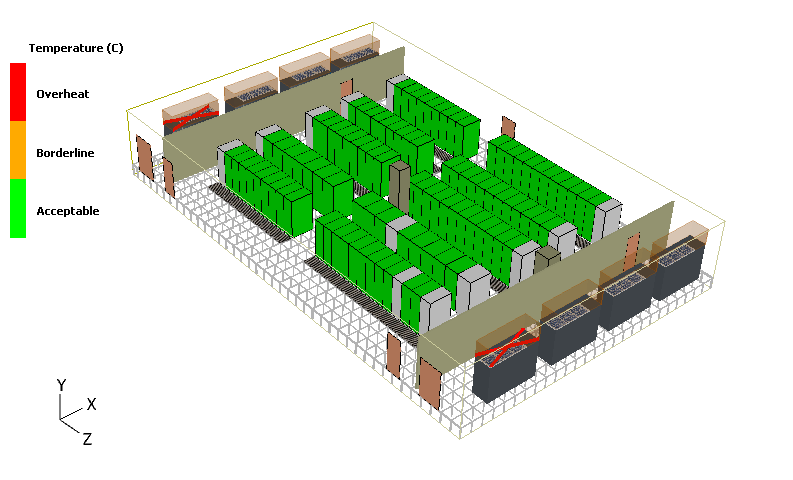

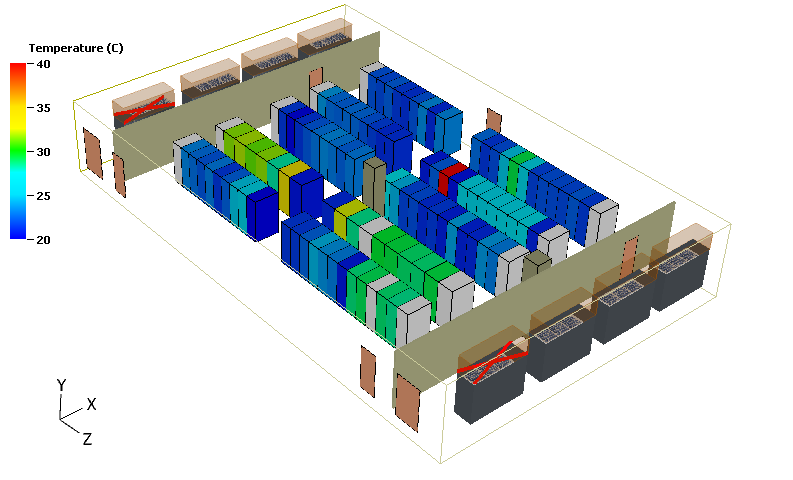

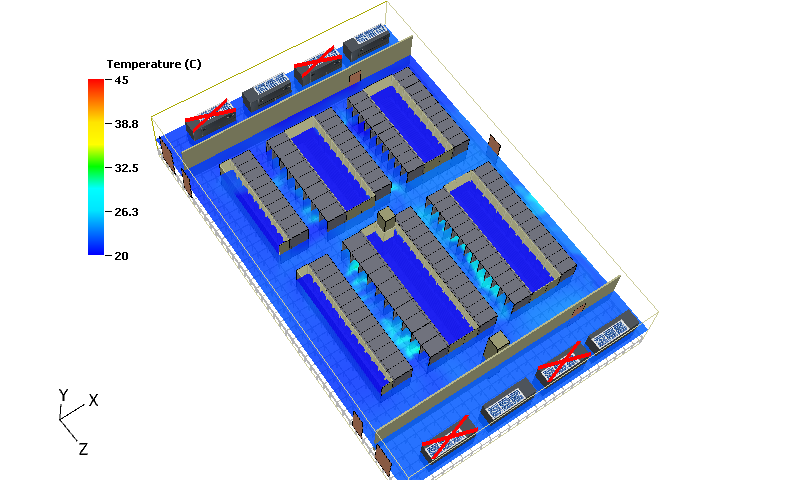

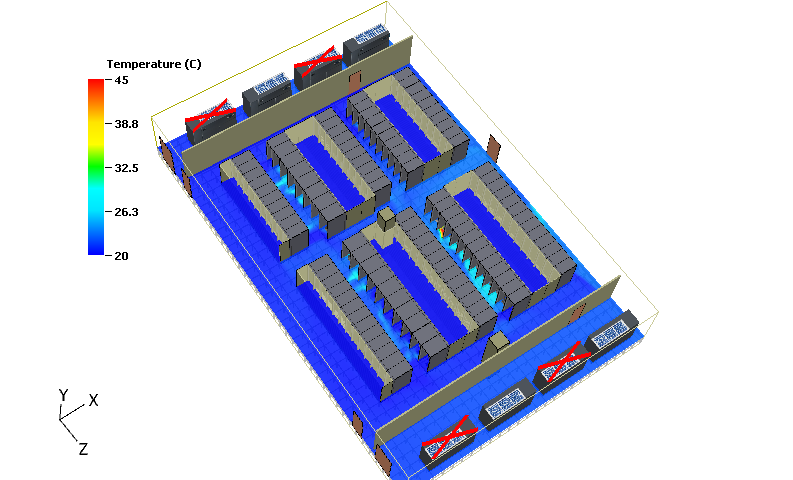

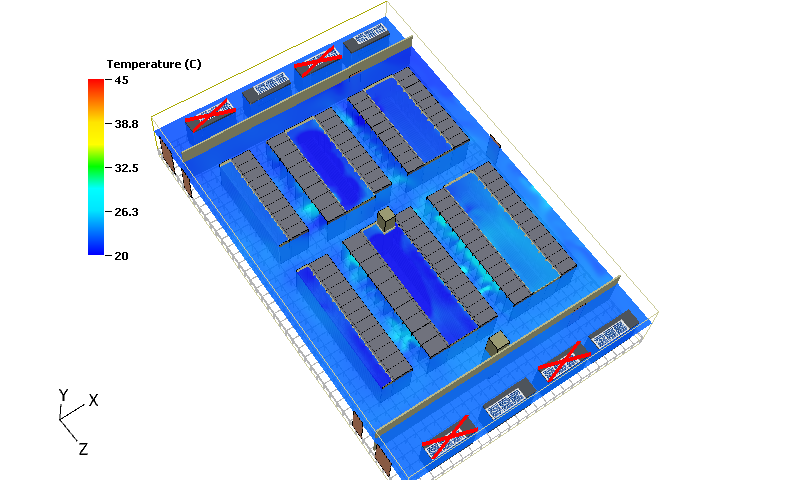

Temperature profiling

Note: Temperature limits are within acceptable range (between 18°C to 28°C)

Outcome – 3 Condition design

| Initial Design condition -1 | Optimized Design-2 | 30kW Added load to Check Life span DC & resilience | ||

| Sr.No. | Benchmarking parameter |

IT load 170kW + 6x22TR (77kWx6no’s cooling- 462kW) |

IT load 170kW + 4x22TR (77kWx4no’s cooling- 308kW) | IT load 200kW + 4x22TR (77kWx4no’s cooling- 308kW) |

| 1 | Weight analysis – Rack & Raised floor | ✔ | ✔ | ✔ |

| 2 | ASHRAE Limits | ✔ | ✔ | ✔ |

| 3 | Over heat racks/Over cooling | ✔ | ✔ | ✔ |

| 4 | Rack intake & outlet temperature | ✔ | ✔ | ✔ |

| 5 | Temp - Cabinet at Bottom ,Halfway, Top | ✔ | ✔ | ✔ |

| 6 | Rack power analysis | ✔ | ✔ | ✔ |

| 7 | Cooling redundancy | ✔ | ✔ | ✔ |

| 8 | CAPEX Savings | ❌ | ✔ | ✔ |

| 9 | Opex savings | ❌ | ✔ | ✔ |

| 10 | Absorb Future IT load | ✔ | ✔ | ✔ |

| Optimum Design Scenario | ❌ | ✔ | ✔ |

Conclusion

Our recommendations : Best scenario to run DC

- Easily we can control 170kW IT load by 4x22TR CRAC units (77kWx4No’s – traditional cooling with 2 units as standby)

With addition of 30kW IT load (170+30 = 200kW) : To check life span & resilience of DC

- 200kW IT load can controlled by 4x22TR CRAC units (77kWx4No’s – traditional cooling with 2 units as standby)

Benefits

- Capex saving of 2 CRAC unit : Current DC requires 6 CRAC units (4Working + 2 Standbys)

- Opex savings of 2 CRAC cooling in terms of space and power, AMC cost

- Opex Cost Savings : Rs/- 30 to 35 lakhs/year on 2 no’s of CRAC (DX type) cooling

- 2 CRAC (77kWx2) unit as standby to maintain resilience