Case Study -4 : Enterprise DC

Facility DC Summery: Brownfield Data center

| Sr No | Description | UOM | Value |

| 1 | Data center area | Sq. ft. | 2347 |

| 2 | Total no’s of racks | No’s | 60 |

| 3 | Installing UPS capacity 3x500kVA No’s | kVA | 1500 |

| 4 | Data center UPS load (IT load) – Presently | kW | 202 |

| 5 | Installed cooling capacity | TR/kW | 185/660 |

| 6 | PAHU units 43TRx2 No’s | TR/kW | 86/301 |

| 7 | DX units 33TRx3 No’s | TR/kW | 99/346 |

| 8 | No’s of supply grills | No’s | 52 |

| 9 | No’s of Return air grills | No’s | 54 |

| 10 | Air distribution system | Type | Ceiling & Room return |

Objective of DCIO services

- Increase energy efficiency hence save energy cost without affecting the performance of the data center (with commited ROI of 16.5months)

- Effective utilization of delivered air flow to the grill level

- Reduces the wastages and re-circulation of cold air

- Actual rack power consumption and recovering lost rack capacity

- Ensure the uptime/availability of IT by avoiding downtime

- Effective utilization of data center white space and rack “U” space

- Energy efficient data center with optimal utilization of capacity

- Predict the impact of cooling failure on the data center resilience (Transient analysis)

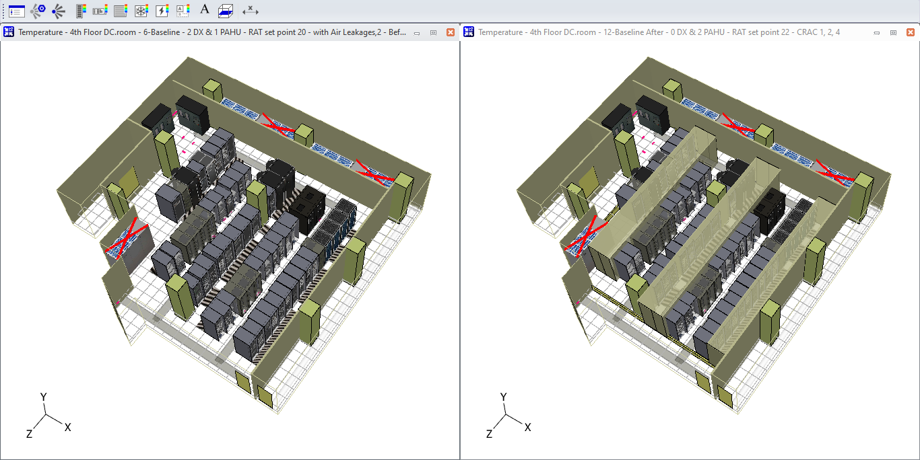

3D Virtual facility

Lets validate 2 simulations scenarios in terms of cooling efficiency (temperature and CFM) with benchmark parameters

Before recommendation

After recommendation

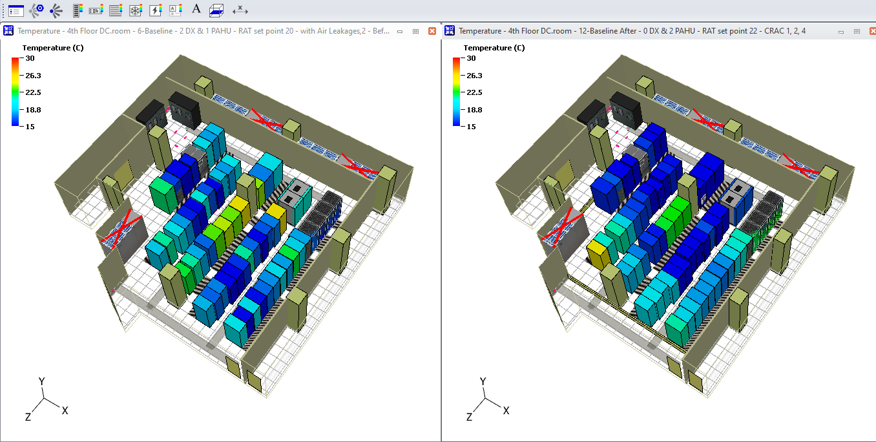

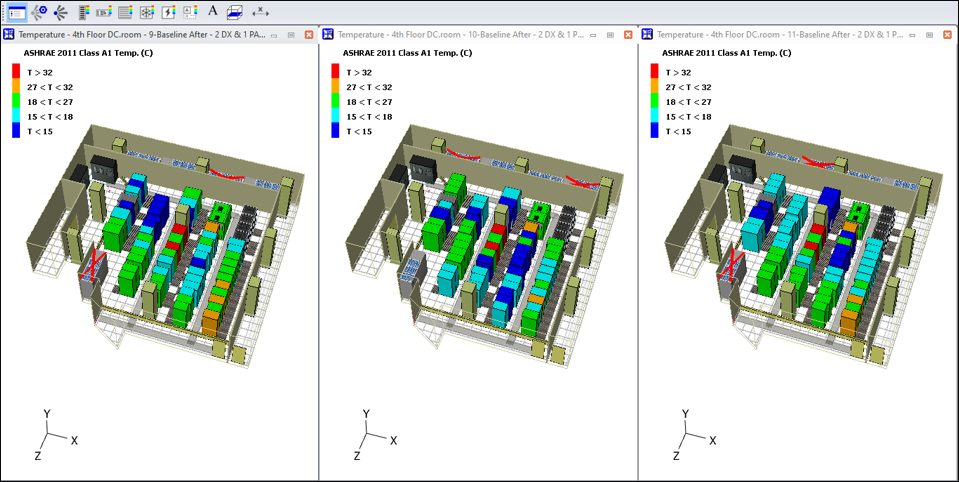

Rack mean inlet temperature

Rack inlet temperatures are high in some of the racks

Rack inlet temperatures limits are acceptable

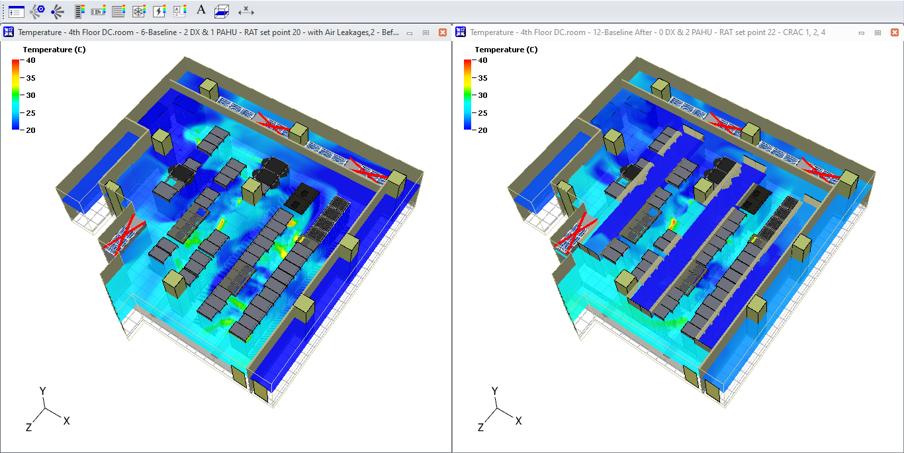

Thermal profile – Top of cabinet

Huge amount of air mixing & hot air short-circuiting

Less amount of air mixing

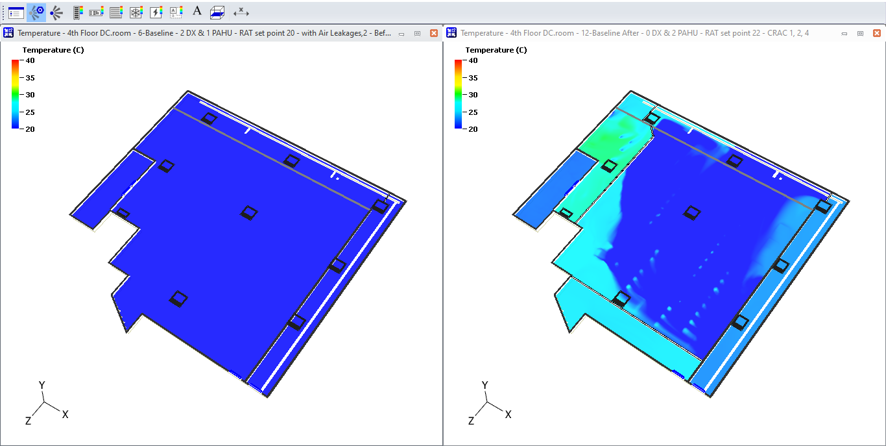

Floor void temperature

Cold air is covering entire false floor area

which results to low CFM delivery

which results to low CFM delivery

Cold air is not covering entire false floor area

which results to high CFM at grill level

which results to high CFM at grill level

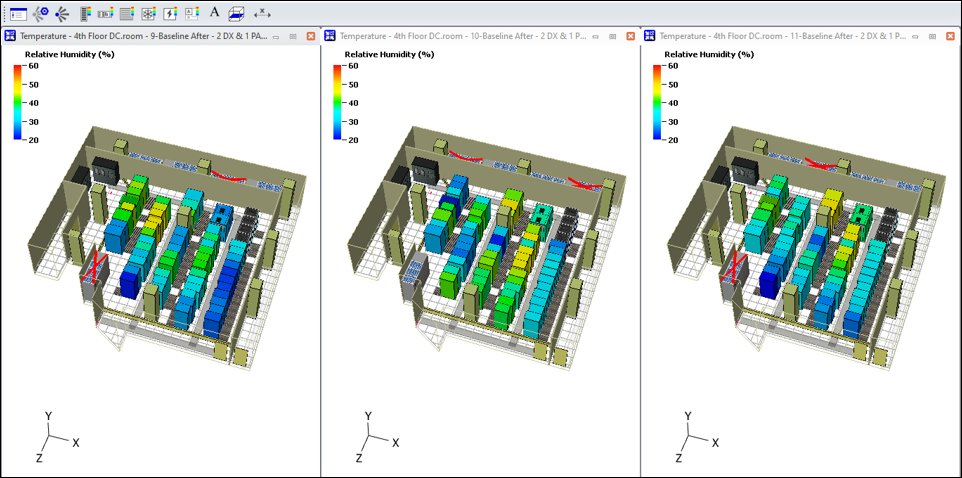

3D Virtual facility

Lets validate 3 simulations scenarios in terms of cooling efficiency (temperature and CFM) with benchmarking parameters

Note: All racks temperature are within acceptable limits and rack no 25 & 27 are temperature is high and these devices are Cisco catalyst devices which throw the air at side of the racks

Note: All racks humidity ranges are within acceptable limits

Transient analysis

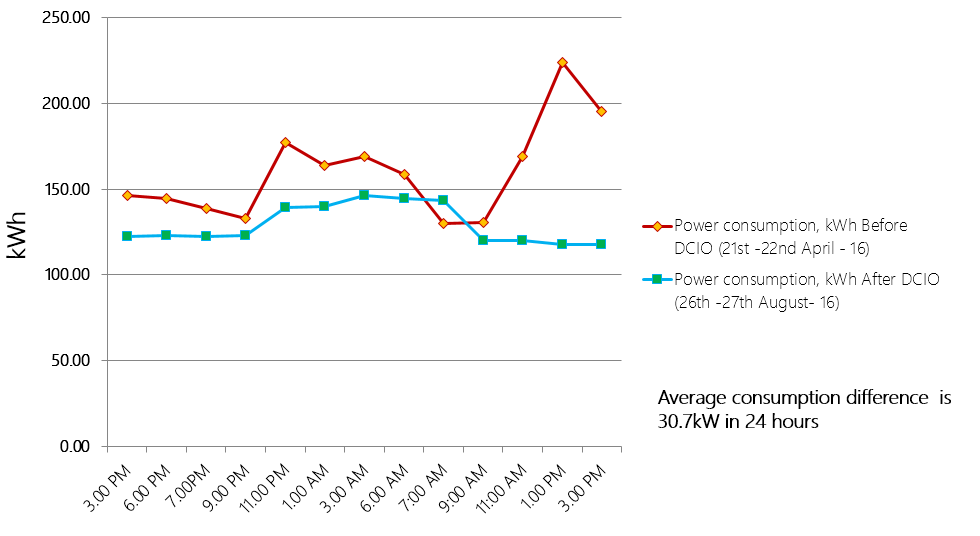

Comparison before and after DCIO

Final Benefits

| Sr No | Description | Units | Before DCIO services | After DCIO services | Improvement Area’s |

| Monitored Data Analysis | |||||

| 1 | Total Energy Consumption | kW | 160 | 129.3 | 30.7kW/hr Savings : Rs/- 21Lakhs/year |

| 2 | Rack intake temperature | ˚C | 17 – 34 | 18 – 22 | Close control |

| 3 | Rack outlet temperature | ˚C | 19 – 36 | 22 – 32 | Close control |

| 4 | CRAC average supply temperature | ˚C | 11 – 18 | 12 – 16 | Efficient |

| 5 | CRAC average return temperature | ˚C | 13.5 – 21 | 22 – 26 | Efficient |

| 6 | Total CFM delivery (CFM Optimization) | CFM | 14516 | 20385 | +5869 |